In the construction, excavation and mining sectors, improving efficiency and productivity is paramount. These industries rely heavily on separating materials quickly and effectively on-site, whether digging soil, processing aggregates or recycling construction waste. Screening buckets, a relatively new innovation, have become a game-changer in this sector, offering significant advantages in material handling. This article explores the features, benefits and applications of screening buckets, focusing on how they are revolutionizing material handling.

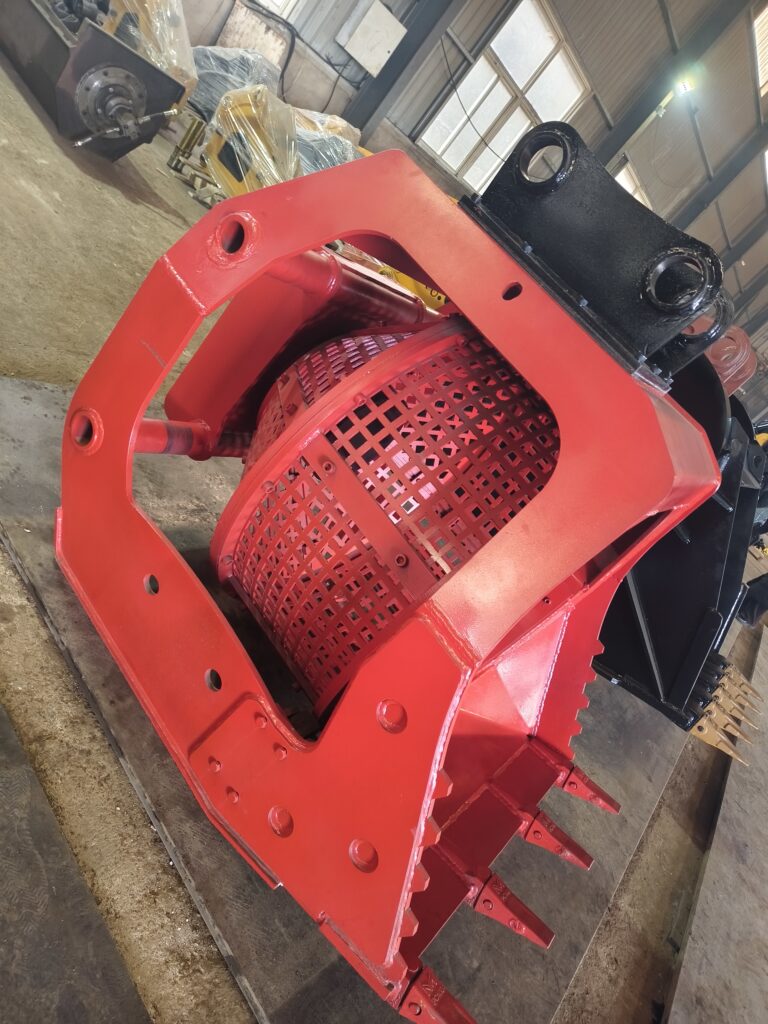

A screening bucket is an innovative device used to screen and separate different types of materials directly on-site. Essentially, it is a modified excavator bucket equipped with a rotating drum or basket structure at the bottom. The drum is fitted with interchangeable screens or meshes of various sizes to sort materials by size. As the host machine digs or scoops up the material, the screening bucket is able to separate the finer particles from the larger particles without the need for additional processing steps.

One of the main benefits of screening buckets is their ability to streamline the material handling process. Traditional methods of separating materials typically require multiple machines, transport and processing stages, which is not only time-consuming but also costly. Screening buckets eliminate these intermediate steps, thereby reducing labor, fuel and transportation costs.

Screening buckets are versatile and can be used with all types of excavators, loaders, and backhoes. Their adaptability makes them suitable for a variety of applications, from topsoil screening and landscaping to mining and quarrying operations. This on-site versatility minimizes downtime and increases productivity.

By processing materials directly on-site, screening buckets help reduce carbon footprint. They are an environmentally friendly choice because they eliminate the need for multiple hauls and reduce associated emissions. Additionally, the screening process separates recyclable materials, promoting sustainable waste management practices.

The efficiency of screening buckets can significantly increase productivity. These attachments can process large amounts of material in a short period of time, allowing projects to move forward quickly. Real-time separation of materials also ensures that only the desired particles are collected, optimizing the final product quality.

Screening buckets are commonly used in construction and landscaping projects to sort and prepare materials such as topsoil, gravel, and sand. They help create a consistent and high-quality base for building foundations, landscaping, and road construction.

In mining and quarrying operations, screening buckets are very useful for separating aggregates and ores. They improve material extraction efficiency and help produce a variety of construction materials such as concrete, asphalt and crushed stone.

Screening buckets are an essential tool for waste recovery due to their ability to separate and process materials directly on site. They can effectively sort and separate construction waste, wood and other recyclable materials, reducing pressure on landfills and promoting a circular economy.

Conclusion

Screening buckets have revolutionized the material handling industry by streamlining processes, improving efficiency and reducing environmental impact. Its versatility, cost savings and positive contribution to sustainable development make it an indispensable tool in construction, excavation, mining and waste management. As technology continues to advance, we can expect further improvements and innovations in screening bucket design, making it an even more important component of modern material handling operations.

If you are interested in the Wenbo Rotary Screening Bucket, please contact us for a quote and more information.