The construction and mining industries are constantly evolving, and so are the requirements for excavator attachments. With technological advances and changing customer needs, the future of excavator attachments looks more exciting than ever.

A key trend in the industry is the increasing focus on automation and intelligence, as well as environmental protection. Manufacturers are developing advanced control systems that allow operators to remotely control and monitor equipment, thereby improving safety and efficiency during operation. This trend is even more important for large projects that require coordination of multiple machines to achieve optimal working results.

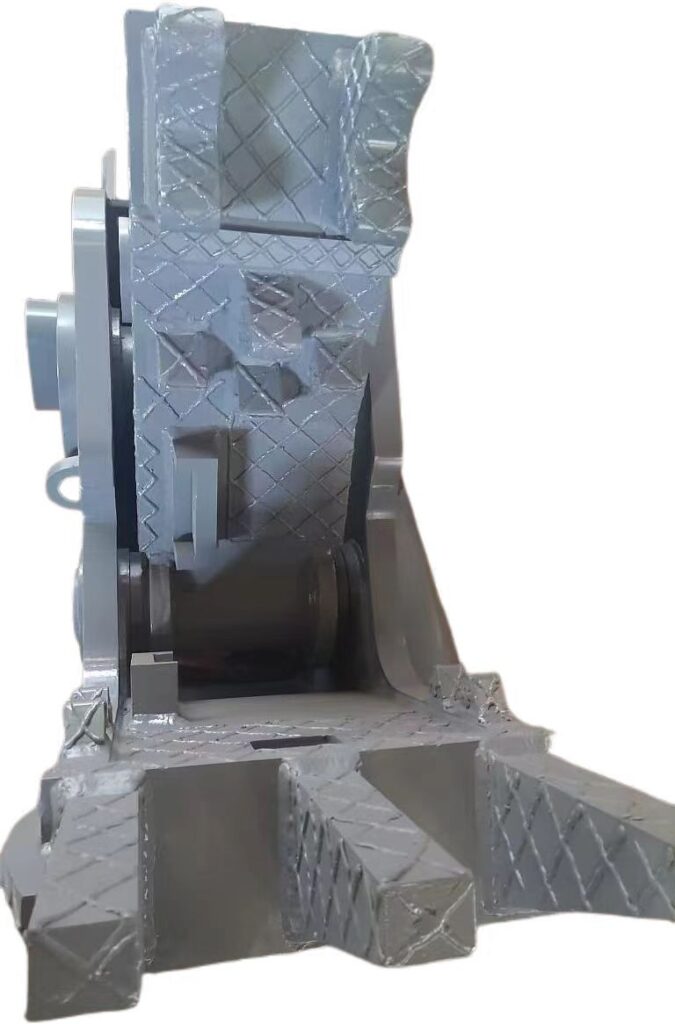

Another important trend is the use of advanced materials and manufacturing processes. High-strength alloys, composite materials, 3D printing and environmentally friendly materials are used to make lighter, stronger, more durable and more environmentally friendly attachments. This not only improves the performance of the equipment, but also reduces its impact on the environment.

Sustainability is also becoming a major concern in the industry. As the world moves towards a more sustainable future, excavator attachments are designed to be more energy-efficient and environmentally friendly. This includes the use of electric and hybrid attachments, as well as the development of recycling and reuse technologies and the use of environmentally friendly materials.

In addition, the demand for multi-functional attachments is also increasing. Operators are looking for attachments that can perform multiple tasks, such as crushing buckets, quick couplers, magnet lift, hydraulic shears, etc., to reduce the need for multiple pieces of equipment and better save time and costs.

Wenbo is at the forefront of these trends and continuously invests in research and development to bring the latest innovations to the market. Wenbo’s products use advanced technology, high-quality materials and customizable options to meet the changing needs of the industry.