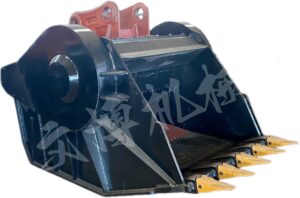

The crushing bucket is an excavator attachment that can quickly crush hard materials such as concrete, rock and scrap metal to improve construction efficiency.

So how should it be maintained?

1. Daily inspection:

Check whether the crushing bucket has cracks, deformation or damage to ensure structural integrity.

Confirm that all connectors and screws are tightened to prevent loosening and malfunctions.

2. Cleaning and maintenance:

Regularly clean the residual materials inside and outside the crushing bucket to avoid accumulation that affects performance.

Use suitable cleaning agents to prevent corrosion and rust.

3. Lubrication and maintenance:

Lubricate moving parts and use suitable lubricants to reduce friction and wear.

Check lubrication regularly to ensure smooth operation of all moving parts.

4. Replace worn parts:

Regularly check the tooth tip, blade and other wearing parts, and replace the parts with severe wear in time.

Choose high-quality replacement parts to ensure performance and life.

5. Regular maintenance:

According to the frequency of use and environment, formulate a maintenance plan and conduct regular comprehensive inspection and maintenance.

Record maintenance status for easy tracking and management.

6. Precautions

Correct operation: Avoid excessive pressure or impact on the crushing bucket to prevent damage.

Avoid improper use: Do not use it for materials or tasks beyond the design range to avoid damage.

Follow the manual: Refer to the manufacturer’s maintenance manual for specific maintenance steps and recommendations.

The above methods can effectively maintain the excavator crushing bucket to ensure its long-term efficient operation, improve construction efficiency and reduce costs.

Wenbo crushing bucket is used for 21-45 ton excavators, weighing about 2 tons. It is welded with NM500 as a whole, which is more wear-resistant and durable; the upper and lower jaw plates are used alternately, and the size of the discharge port can be adjusted freely; it is equipped with a imported hydraulic motor as standard, with a 12-month warranty period. It is generally used with a screening bucket.

Features:

1. Our crushing bucket uses belt drive to reduce the damage of crushing vibration to the hydraulic system.

2. Simple and convenient installation, no need to connect forward and reverse, ordinary crushing hammer pipeline is sufficient.

3. The opening width and height of the crusher bucket are increased, and the output is increased.

4. The excavator can operate at low working pressure, and 23MPA hydraulic pressure can achieve high-yield crushing.

5. Even if the jaw plate is worn, the shape and size of the output can be guaranteed to meet customer requirements.

6. The efficient hydraulic system of the crusher bucket can ensure that the hydraulic system will not overheat even under severe high temperature or high-intensity continuous operation conditions.

If you are interested in Wenbo crushing bucket, please contact us.